Mastering the Art of Finger Joints: Essential Techniques for Woodworking Excellence

Finger joints, also known as box joints, are a fundamental technique in woodworking that exemplify both precision and craftsmanship. These joints are pivotal in creating strong, durable connections between wooden pieces, especially in box-like constructions such as drawers, cabinets, and frames. Understanding the different types of finger joints and their applications can significantly enhance the quality and durability of your woodworking projects.

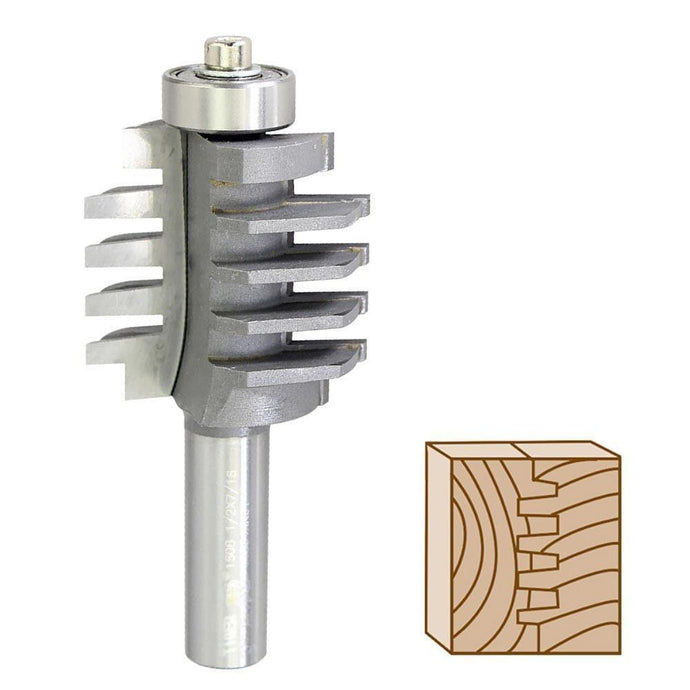

At its core, a finger joint is a type of interlocking joint where two pieces of wood are connected by a series of protruding and recessed ˇ®fingers' that fit together like puzzle pieces. This design not only provides a robust mechanical bond but also showcases the joinery skill involved. The most common types of finger joints include the straight finger joint, the tapered finger joint, and the dovetail finger joint, each offering distinct advantages and aesthetic qualities.

The straight finger joint is the simplest and most widely used type. It features evenly spaced, perpendicular fingers that create a clean and straightforward connection between wood pieces. This joint is especially favored for its ease of construction and its ability to provide strong, reliable joints without requiring advanced tools or techniques. The straight finger joint is often used in making drawer boxes, storage containers, and other projects where a simple, functional joint is sufficient.

In contrast, the tapered finger joint adds a touch of complexity and refinement to woodworking projects. In this variant, the fingers are cut at an angle rather than perpendicular to the wood surface. This tapering can create a more visually interesting joint and is often used in more decorative or high-end furniture pieces. The tapered finger joint requires precise angle cutting and alignment, making it a bit more challenging to execute but offering a unique aesthetic appeal and enhanced strength due to the increased surface area of contact between the joined pieces.

The dovetail finger joint combines the robust, interlocking nature of traditional dovetail joints with the simplicity of finger joints. This hybrid approach provides a blend of both worlds: the strength and stability of dovetail joinery with the straightforward construction process of finger joints. The dovetail finger joint features a series of tapered, interlocking fingers that fit together in a manner similar to dovetail joints but with a more modern, streamlined appearance. This type of joint is commonly used in high-quality cabinetry and fine furniture, where both strength and visual appeal are paramount.

While these are the primary types of finger joints, there are several other variations and modifications that woodworkers might employ based on their specific needs and preferences. For instance, some craftspeople might use stepped finger joints, where the fingers are staggered in a stepped pattern to enhance the joint's visual appeal or to accommodate specific design requirements. Others might experiment with end grain finger joints or other innovative configurations to achieve unique effects or functional benefits.

The choice of finger joint type often depends on the project's requirements, including the desired strength, aesthetic quality, and level of difficulty the woodworker is prepared to undertake. Straight finger joints are ideal for beginners or projects where simplicity and functionality are key. Tapered finger joints and dovetail finger joints, on the other hand, are better suited for more advanced projects where the visual and structural qualities of the joint are of greater importance.

In terms of construction, achieving a precise finger joint involves careful measurement, alignment, and cutting. Many woodworkers use specialized jigs or machines to ensure accuracy and consistency in the finger joint cutting process. A well-executed finger joint not only ensures a strong, durable connection but also demonstrates the woodworker's skill and attention to detail.

Ultimately, mastering finger joints is an essential skill for any woodworking enthusiast or professional. Each type of finger joint offers unique benefits and can contribute to a project's overall quality and appeal. By understanding the different types of finger joints and their applications, woodworkers can make informed decisions about which joinery technique best suits their needs and project goals. Whether you're building a simple drawer box or a sophisticated piece of furniture, incorporating well-crafted finger joints can elevate your work and showcase your woodworking expertise.